The department Process Equipment within Ravebo designs, produces, and implement advanced wet gas scrubbers. Over the years we have accumulated extensive knowledge of absorption and separation technology through research, development, and practical experience. Additionally, we offer comprehensive maintenance and optimization services for current installations or specific components, customized to their unique areas of specialization.

The department Process Equipment within Ravebo designs, produces, and implement advanced wet gas scrubbers. Over the years we have accumulated extensive knowledge of absorption and separation technology through research, development, and practical experience. Additionally, we offer comprehensive maintenance and optimization services for current installations or specific components, customized to their unique areas of specialization.

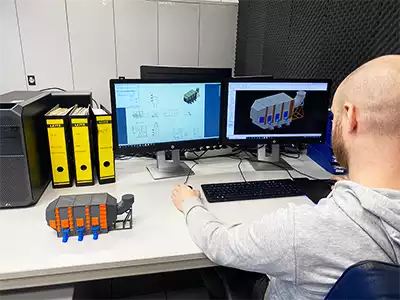

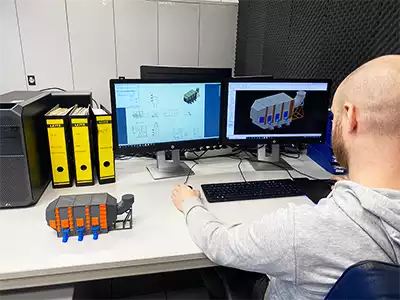

Ravebo provides a variety of gas cleaning systems, which consist of both vertical and horizontal scrubbers. These systems serve various purposes, such as quenchers, droplet separator systems, dust scrubbers, chemical scrubbers, and odour scrubbers. The selection of materials for these systems is done meticulously, taking into consideration the specific application requirements. The materials can range from plastic options like PE, PP, GFK to different types of stainless steel. In order to offer a comprehensive understanding of the system, Ravebo utilizes an Inventor package to create 3D presentations using Autodesk Inventor. These presentations can be seamlessly integrated into the customer's production installation. This approach not only reduces lead time and cut costs but also enables the customer to visualize the final outcome during the quotation stage.

The Process Equipment Department has the capability to offer the gas cleaning system either as a component of a larger project or as a complete turnkey solution. In this regard, Ravebo not only provides the scrubber itself, but also manages the entire process of installation, connection, and commissioning. The installation encompasses comprehensive piping, control cabinets, auxiliary equipment like dosing systems and rotating separators, pumps, fans, and all essential instruments. Moreover, the scrubber can be enhanced with a PLC control system, which guarantees seamless operation of the installation. This control system is programmed by Ravebo's skilled engineers and implemented directly at the project site.

Ravebo possesses essential competencies to successfully execute these projects, including a flexible organization, a design department with over 30 years of experience, an in-house assembly service, expertise in turnkey projects, and an application-oriented and pragmatic approach.

Ravebo has well-equipped workshops in which construction, welding and assembly work takes place for custom-made process installations and small series systems. Custom-made installations are handled on a project basis, whereby our draftsmen-constructors can develop the 3D designs from the engineering department using Autodesk Inventor, in collaboration with the production department, into production drawings and can also perform stress analysis.

Ravebo has well-equipped workshops in which construction, welding and assembly work takes place for custom-made process installations and small series systems. Custom-made installations are handled on a project basis, whereby our draftsmen-constructors can develop the 3D designs from the engineering department using Autodesk Inventor, in collaboration with the production department, into production drawings and can also perform stress analysis.

In addition to realizing new-build installations, we also carry out renovation and optimization of process installations that often need to be carried out on site at the customer during a stop period.

For small series and for product improvement, we have an equipped construction workshop with, among other things, a lathe, press brake, roller and profile roller, so that we can respond well and quickly to customer-specific wishes.

In our welding workshop we use Fronius welding equipment and various welding principles, including MIG/MAG and TIG, and process, due to the application of installations and systems, especially stainless steels such as AISI 304 and 316.

Inventor Drawing Installations and systems can be supplied complete with appendages, instrumentation, control cabinet and PLC control system. Here we use renowned brands including KSB, Eriks, Endress+Hauser, Rittal, Phoenix and Siemens.

Inventor Drawing Installations and systems can be supplied complete with appendages, instrumentation, control cabinet and PLC control system. Here we use renowned brands including KSB, Eriks, Endress+Hauser, Rittal, Phoenix and Siemens.

The motor and instrumentation list is drawn up in consultation with the customer, and our engineers use Eplan software for the selection of cabling, setting up the electrical diagrams and the design of the control cabinet layout.

Switch boxes and control panels are then assembled, wired and tested in our panel construction department, whereby an ergonomic and height-adjustable worktable can be utilized.

To ensure a correctly functioning control system, our engineers draw up a functional description in consultation with the customer. This is translated by our programmers, who often use PLC systems from Siemens, among others. Network/bus technologies can be used to control and/or read components.

We can also use process analyzers to control the installations. These systems can be configured and assembled by our engineers and can be installed on the process installation or placed on its own skid. The maintenance and calibration of these systems is performed by our service engineers.

Produced Gasmet Calibration systems and installations are assembled as completely as possible in our assembly workshop for internal collection, performing various tests and, if desired, a FAT with our customer/client.

Produced Gasmet Calibration systems and installations are assembled as completely as possible in our assembly workshop for internal collection, performing various tests and, if desired, a FAT with our customer/client.

Our technicians can assemble and connect the installation at the customer's location, after which the installation is commissioned by a commissioning engineer together with the customer (SAT). It is possible to provide training/instructions to operational employees of the customer, so that they become familiar with the installation and its functioning.

If desired, the installation can be monitored remotely, in consultation with the customer and its IT / network specialist, whereby data logging is possible locally or in the cloud.

Get in touch with our scrubber specialist

Boost your industrial processes with our advanced wet gas scrubbers. Our specialist is ready to guide you towards efficiency, productivity, and environmental compliance. Connect with us now for expert advice, custom solutions, and quick responses. Let's find your perfect scrubber solution today.