BTEX Emissions in Industrial Processes

Challenges and Solutions in Reducing BTEX Emissions

Customised advise from one of our specialists.

Fill in the form below and we will contact you as soon as possible.

Understanding BTEX

Composition and Industrial Impact

Emissions and odor nuisance frequently occur at asphalt manufacturers, printing companies, agricultural companies, paint spray booths, adhesive applications, and in the plastics processing and coating industry. The emissions from these solvents are mainly volatile hydrocarbons such as benzene, toluene, ethyl benzene, and xylene, also known as BTEX.

Due to strict environmental requirements, companies must act appropriately to reduce the emissions of these components. This depends on the extent to which the production process is continuous or intermittent and to what extent the composition and concentration vary. Unfortunately, the concentrations are often too low for reuse.

BTEX is an acronym that refers to a small group of aromatic (due to their sweet odor) hydrocarbons, specifically benzene, toluene, ethyl benzene, and xylene. These are all volatile organic compounds that are important in petrochemistry, where they play a role in almost all aspects of chemical synthesis, especially plastics and fuels. They are extracted from petroleum and used as solvents. BTEX are harmful to health and can have effects on the central nervous system.

From PET Bottles to Asphalt

BTEX's Wide Industrial Reach

BTEX are good solvents and flammable, and because of these properties, they are widely used, such as basic products for preservatives, raw material for plastics, elementary component for use in cosmetics, components of thinner, solvents of organic substances such as resins, coatings, inks, and fats, in the production of polyester polyethylene terephthalate (known from PET bottles), and finally in asphalt and fuels.

Get in touch with us

Understanding the Health Risks Associated with BTEX Exposure

Potential Health Hazards of Benzene, Toluene, Ethyl Benzene, and Xylene

Benzene is carcinogenic when inhaled in high concentrations for an extended period of time. Toluene causes, when exposed to high concentrations for long periods of time, memory problems. Inhaling substantial amounts causes dizziness and nausea. Xylene can cause headaches, dizziness, nausea, or unconsciousness when inhaled. Ethyl benzene irritates the eyes, skin, and respiratory tract. At high levels of exposure, damage can occur to organs such as the liver and kidneys.

Environmental Impact of VOCs and the Role of Climate Policy in Air Pollution

Complex Effects of Climate Policy on Air Quality and VOC Regulation

Volatile organic compounds (VOCs) react under the influence of sunlight to form ozone, which at ground level is very harmful to the health of humans, vegetation, and animals. Ozone also leads to smog formation in sunny and windless weather (see also Smog Regulation 2010). Traffic and transport are the main sources of benzene emissions, contributing approximately 50%. Other sources are combustion in wood stoves and fireplaces (about 20%), the storage and transshipment of coal and the like, the chemical industry and asphalt production. The largest toluene emissions occur during the production, transport, and use of gasoline. Lesser amounts are released in industrial wastewater discharges and land disposal of sludges and petroleum wastes. Xylene and Ethyl benzene are emitted to the atmosphere primarily as fugitive emissions from industrial sources (e.g., petroleum refineries, chemical plants), in automobile exhaust, and through volatilization from their use as solvents.

Many measures against climate change also have consequences for air pollution. In addition to greenhouse gas emissions, this also reduces emissions of particulate matter and ozone-forming substances (nitrogen oxides, volatile organic compounds, and carbon monoxide). A direct effect of this is a reduced risk of summer smog because climate policy slows down the temperature increase and thus the formation of ozone. Indirect effects on air pollution through climate policy are also possible. However, the consequences do not always have to be favorable.

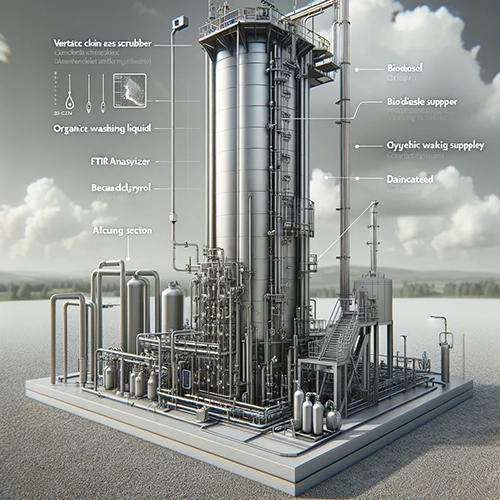

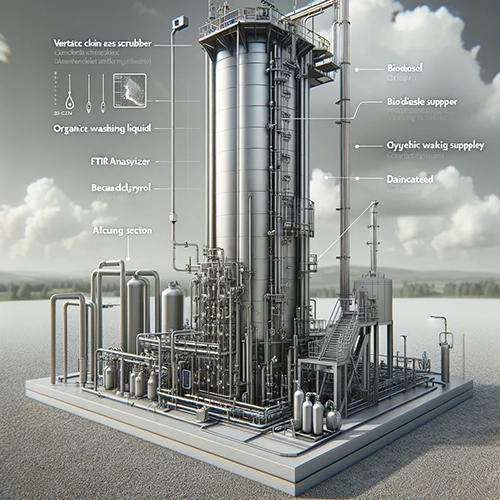

Effective BTEX Removal Techniques Using Wet Gas Scrubbers

Optimizing Wet Gas Scrubber Efficiency for BTEX Removal

Provided it is configured correctly and uses the right washing liquids, BTEX can be excellently removed from a gas stream with a wet gas scrubber. Since BTEX are not soluble in water an organic washing liquid is required. For instance, Ravebo uses (bio)diesel with alcoholic additives to absorb BTEX at low temperatures. The supply of biodiesel and glycerol and the drainage section will be based on the measurement of the Pyxis GC analyzer which is mounted in the exhaust of the scrubber.

Game-changing benefits

Discover the game-changing benefits of scrubbers and propel your business forward with our free whitepaper download.

BTEX Emission Control Podcast

Understanding Effective Solutions

In this podcast episode, we dive into the crucial topic of BTEX emissions—harmful compounds such as benzene, toluene, ethylbenzene, and xylene, often released during various industrial processes. Understanding these emissions' impact on health and the environment, we explore advanced solutions like Ravebo's wet gas scrubbers designed to effectively capture and reduce BTEX compounds. Join us as we discuss how innovative technology is making industrial processes safer and more sustainable, with insights into practical applications and industry benefits.

Listen now!

The Mechanics and Efficiency of Open Spray Wet Gas Scrubbers

Advanced Nozzle Design for Optimal Gas and Dust Absorption

The wet gas scrubber is an open spray system. Open spray systems operate based on the difference in velocity potential between liquid droplets and the incoming gas. The scrubber works according to a closed-loop pump system in which the liquid is discharged with moderate pressure to nozzles with the objective of getting a homogeneous droplet distribution and an equal spray pattern. The droplet size is important since ultrafine droplets have a particularly large surface-to-volume ratio. The exceptionally fine droplets create a fine mist, which results in an efficient capture of particles. The spray absorbers operate relatively simply, are very maintenance-friendly, and have extremely low energy costs.

Due to the lack of random packing or a structural packing, the open spray absorbers have a minimal pressure loss and are virtually insensitive to contamination, which normally causes a larger pressure difference. The spray system consists of multiple removable spray lances with spray nozzles, some of which are co-current and some of which are counter-current. The positioning of these spray nozzles in the scrubber is of the utmost importance for optimal gas treatment because they capture particles because of the intensive contact between the washing fluid and the process gas. The clogging-free tangential nozzles create fine droplets with a homogeneous spray pattern to capture as many dust and gas particles as possible. Optimal contact of fine liquid droplets with gases and dust particles will lead to a high absorption of polluting particles and gases.

Innovative Air Quality Monitoring with Pyxis GC BTEX Chromatograph

Revolutionizing BTEX Detection with Pyxis GC BTEX Chromatograph

The Pyxis GC BTEX is an exceptional environmental gas chromatograph that offers unparalleled reliability and versatility for efficient monitoring. It is the first of its kind, as it operates without the need for a carrier gas, making it truly unique. With this innovative technology, you can remotely monitor BTEX (Benzene, Toluene, Ethylbenzene, and Xylene) levels in ambient air, ensuring compliance with the EN14662-3:2015 standard. Unlike traditional gas chromatographs, this instrument eliminates the requirement for gas cylinders, as it utilizes ambient air as the carrier gas. This feature allows for easy installation in any setting without the need for additional staff or gas cylinders.

Pyxis GC BTEX utilizes the Micro-Electro-Mechanical (MEMS) System of microfluidics to selectively pre-concentrate and separate gases through gas chromatography. The quantification of peaks is achieved by a Photo Ionization Detector (PID). The BTEX compounds present in the gas sample are physically separated using a micro column chip, which is based on proprietary technology. Additionally, Pyxis GC is equipped with an auto-check system that ensures the verification and potential correction of instrumental drift over time, thereby guaranteeing the quality of data. These features enable Pyxis to deliver the same level of analytical quality as laboratory instruments in field applications, however Pyxis is highly portable.

Pyxis GC BTEX is fully compatible with cloud service, for data monitoring and management purposes. The software automatically stores and archives analysis data, enabling users to view real-time and historical data through the creation of charts, tables, graphs, and other statistical analyses. Additionally the software allows users to set customized alarms on the collected data and receive notifications via SMS or email.

Pyxis GC BTEX has the capability to be integrated into the monitoring network, providing real-time data on the concentration of BTEX in the air. This valuable information can be utilized to gain a more comprehensive understanding of the air quality, complete with accurate geolocation. Consequently, it aids in the formulation of an effective environmental plan that aims to mitigate the adverse effects of pollution on the population.

Get in touch with our scrubber specialist

Boost your industrial processes with our advanced wet gas scrubbers. Our specialist is ready to guide you towards efficiency, productivity, and environmental compliance. Connect with us now for expert advice, custom solutions, and quick responses. Let's find your perfect scrubber solution today.