Scrubber installation for fluorine

In two reactors, calcium phosphate is dosed as a powdered reagent in phosphoric acid at 90 °C. During the reaction, hydrogen fluoride is released, the emissions must meet the requirements according to Vlarem II.

In two reactors, calcium phosphate is dosed as a powdered reagent in phosphoric acid at 90 °C. During the reaction, hydrogen fluoride is released, the emissions must meet the requirements according to Vlarem II.

Process condition

| Gas flow | : | 7,500 Am3/h |

| Design temperature | : | 58 °C |

| Current pressure | : | 932 mbar (absolute) |

| Maximum load of fluorine | : | 300 g/h |

| Maximum dust load | : | 1,600 mg/m3 |

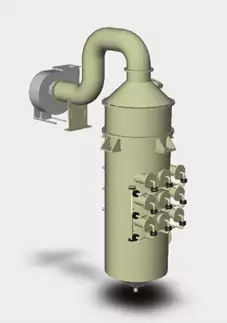

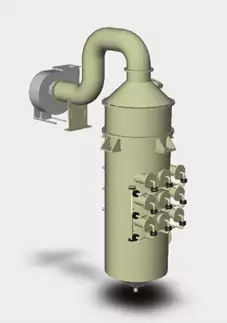

A countercurrent scrubber installation (vertical construction, interior arrangement), including separately installed liquid buffer, which is specially configured for a process gas flow with a maximum flow of 7,000 Am3/h. The installation is fully equipped with PLC control, instrumentation, pumps, centrifugal fan, and fittings. The scrubber housing is equipped with two flange divisions so that in case of periodic maintenance the pre-separator and final separator can be removed for maintenance or cleaning. The column is made of PP.

Get in touch with us

Scrubber pump

The magnet drive centrifugal pump (manufactured by Iwaki, with Siemens motor) is built directly to the buffer tank of the scrubber and pumps the washing liquid around in a closed loop. The pump flow rate and the discharge pressure are constant. The pump is equipped with a blocker option by means of manually operated ball valves (manufactured GF+) and a locally readable pressure transmitter (manufactured Endress & Hauser) on the press side to assess the status of the nozzles. A higher pump pressure compared to the initial pressure may mean that nozzles may be clogged. Materials: ETFE / SIC

The magnet drive centrifugal pump (manufactured by Iwaki, with Siemens motor) is built directly to the buffer tank of the scrubber and pumps the washing liquid around in a closed loop. The pump flow rate and the discharge pressure are constant. The pump is equipped with a blocker option by means of manually operated ball valves (manufactured GF+) and a locally readable pressure transmitter (manufactured Endress & Hauser) on the press side to assess the status of the nozzles. A higher pump pressure compared to the initial pressure may mean that nozzles may be clogged. Materials: ETFE / SIC

Level control

The washing liquid level in the buffer tank is continuously measured with an ultrasonic level meter (manufactured Endress & Hauser) for the different working and alarm levels. In addition to the conductivity measurement, the signals can be used to control the electrically driven discharge and replenishment valves. The supply of fresh replenishment water can be controlled by means of a flanged electrically operated ball valve (24 VDC, manufactured GF+). The discharge of washing water depends on the washing water quality and must take place on the basis of conductivity (make Endress & Hauser). The buffer tank is equipped with a flanged electrically operated ball valve to control the discharge.

Conductivity

The buffer is equipped with a Flange DN50 in which the conductivity sensor (make: Endress+Hauser) will be mounted. The sensor is supplied with a fixed cable and a transmitter which is mounted in the control cabinet. The conductivity sensor is a digital inductive conductivity sensor with high chemical resistance (PFA and PEEK).

Pressure transmitter

Compact pressure transmitter with robust ceramic oil-free measuring cell. Resistant to frequent overload and very deep vacuum. Suitable for both pressure and level applications. Display operation with LCD and push button on display. Manufactured of PVDF with Kalrez seal.

Fan

Fan to bridge the pressure loss over the scrubber installation (including connecting ductwork). The fan is fully equipped in PP.

Dimensions

| Gas entry/exit | : | DN500 |

| Diameter scrubber | : | ø 1.400 mm |

| Buffer dimensions | : | ø 1.200 x 1.000 mm (D x H) |

| Total height of column | : | ca. 3.400 mm |

| Materials | : | PVDF and PP |