Gas cleaning with scrubbers using additives

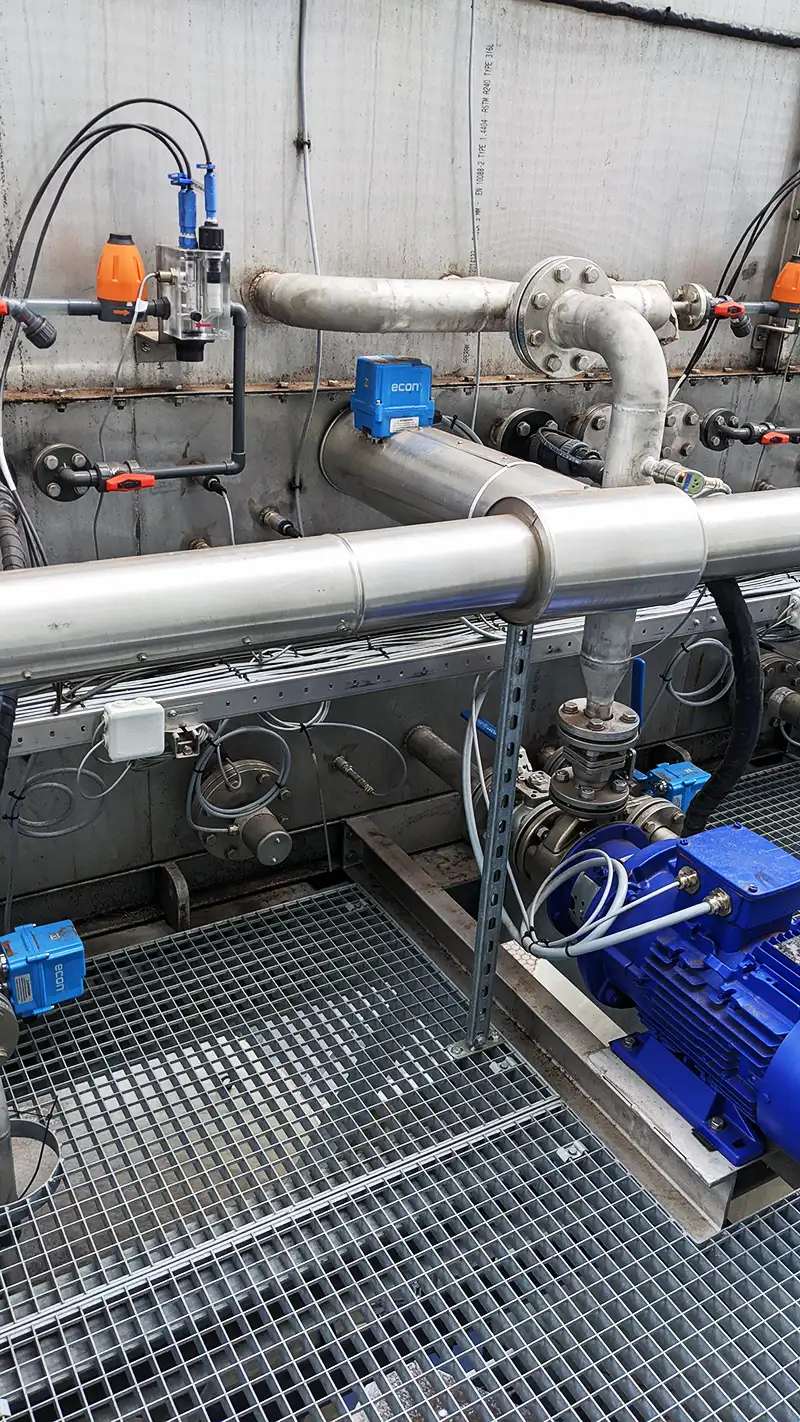

The washing liquid is recirculated by means of a centrifugal pump which is connected on the suction side to the liquid buffer in which the washing liquid is stored. In certain areas where only (relatively) hard water is available a water softener can be used for the makeup water. The hardness of the water has a major influence on the efficiency of the scrubber process. The washing liquid is recirculated and will be periodically drained based on certain parameters. The liquid level is then restored with fresh makeup water. When this fresh water contains (a lot of) magnesium and calcium this will lead to high concentrations of salts which will increase the hardness because during the discharge process the salts will largely remain in the liquid buffer. This can be avoided when using a water de-ironing system. The alternative is to discharge a lot of washing liquid, but this will then result in an excessively high-water consumption.

The washing liquid is recirculated by means of a centrifugal pump which is connected on the suction side to the liquid buffer in which the washing liquid is stored. In certain areas where only (relatively) hard water is available a water softener can be used for the makeup water. The hardness of the water has a major influence on the efficiency of the scrubber process. The washing liquid is recirculated and will be periodically drained based on certain parameters. The liquid level is then restored with fresh makeup water. When this fresh water contains (a lot of) magnesium and calcium this will lead to high concentrations of salts which will increase the hardness because during the discharge process the salts will largely remain in the liquid buffer. This can be avoided when using a water de-ironing system. The alternative is to discharge a lot of washing liquid, but this will then result in an excessively high-water consumption.

Dosing systems with storage tanks, with adjustable membrane pumps for various chemicals, are also an indispensable part of the scrubber installation. The removal of soluble contaminants from the gas can be done by using only a lot of washing water as an open flush system. This means that the washing water is continuously discharged and refreshed and not pumped around. The contaminants will be absorbed into the water and then discharged through the drain. The water consumption associated with this is unjustified under the current (environmental) conditions and also unaffordable.

Another reason for applying chemicals in the washing water may be necessary due to water-insoluble or non-degradable contaminants in the gas that should not be drained or disposed. Therefor it is necessary to mix additives to the washing water that react with the contaminants. The choice of chemicals is determined by the nature of the contaminants but can also be determined based on the customer's capabilities. It is not always permitted to simply use chemicals and then dispose the residual products. In these situations, alternative cleansing agents should be added, or a modified configuration of the scrubber will have to provide a solution.

The chemicals are generally dosed directly into the washing water. As a result, we no longer talk about washing water but about washing liquid. The recirculated washing liquid is brought into contact with the contaminants in the gas where they are absorbed and then jointly drop back into the liquid buffer. The content of the liquid buffer is determined by the reaction rate or half-life of the impurities in the washing liquid. In general, it can be stated that a slow response requires a large system content. The intention is that the reaction has been conducted as much as possible into a stable residual product before the washing liquid is brought back into contact with the polluted gas via the recirculation by the pumps. If the reaction is not sufficiently completed, there is a potential risk that contaminants will be released back into the gas.

In addition, in the event of a reaction that has not been fully impinged, additional problems may arise at varying concentrations of the contaminants in the gas. The pollutant gases present in the washing liquid, prefer to be in balance with the concentration of pollutant gases in the entrained gas stream. This phenomenon is described in Henry's Law regarding the phenomena of the equilibrium situation of (gas) concentrations.

Dosing chemicals will eventually have to lead to a breakdown of harmful contaminants or a transformation into harmless components that can be easily disposed of and processed. Secondly, accurate dosing with the right chemicals prevents extreme water consumption.