Gas Scrubbers for Well Stimulation Vessels

Safe treatment of sour, toxic and corrosive flowback gases offshore

Why well stimulation vessels need dedicated gas scrubbers

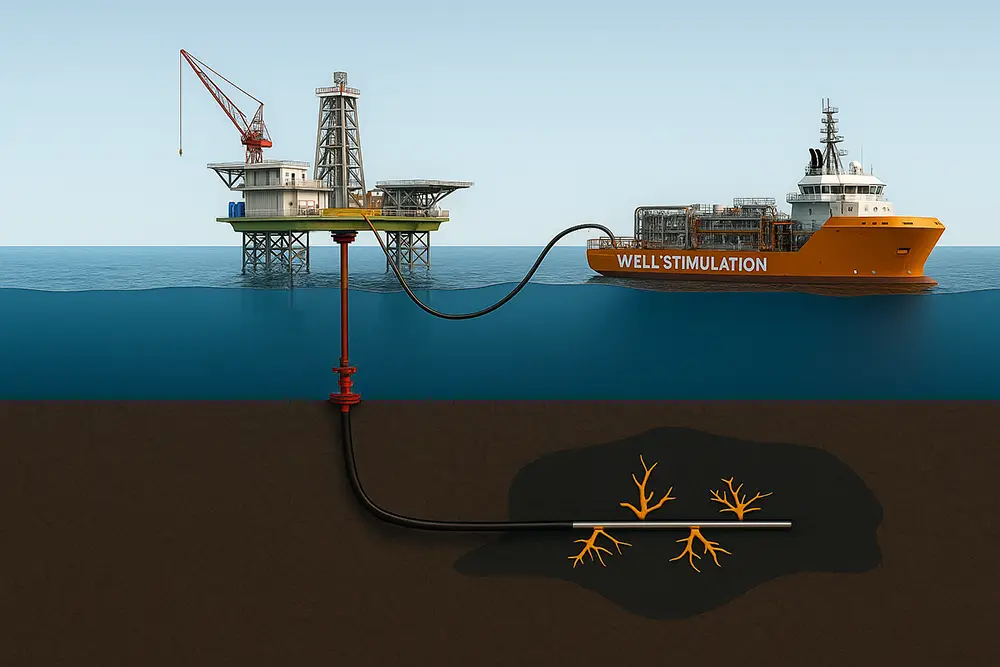

A well stimulation vessel is a specialised offshore ship used to improve production from existing oil and gas wells. Instead of drilling a new well, the vessel pumps stimulation fluids such as acids, solvents or tailor-made chemical blends into the reservoir to dissolve formation damage, remove scale or increase permeability. As these treatments react downhole, a mixture of gas and liquids flows back to the vessel.

That flowback can contain highly sour, toxic and corrosive gases such as hydrogen sulphide, BTEX aromatics and acid vapours, often in rapidly changing concentrations. Uncontrolled venting is a serious safety risk for the crew and can easily violate offshore environmental regulations. A dedicated gas scrubber provides a controlled, engineered way to remove these contaminants before the gas is vented or sent to a flare.

Typical gas composition on a stimulation vessel

The exact composition of the flowback gas depends on the reservoir and chemistry used, but in practice the same families of components show up again and again.

- Hydrogen sulphide (H₂S) – extremely toxic and corrosive, must be removed immediately.

- Methane and light hydrocarbons – flammable, explosive and subject to emission limits.

- BTEX compounds – benzene, toluene, ethylbenzene and xylene; hazardous aromatics.

- CO₂ – naturally occurring, can form corrosive carbonic acid in liquids.

- Acid vapours – e.g. from HCl or other stimulation acids.

- Fine aerosols and chemical mist – generated by high-pressure pumping operations.

Without proper gas treatment these mixtures can create hazardous working conditions on deck, accelerate corrosion of equipment, and trigger environmental non-compliance. For professional offshore operations, a robust scrubber system is therefore not optional – it is a core safety device.

How a gas scrubber fits into the well stimulation process

On a well stimulation vessel, the gas scrubber is installed downstream of the primary flowback separation. Liquids are removed first in a separator or knock-out drum. The separated gas is then routed through one or more scrubbing stages where contaminants are absorbed, neutralised or oxidised. A high-efficiency demister removes remaining droplets so that the outlet gas can be safely vented or sent to a thermal oxidiser or flare.

For sour and mixed gases, an alkaline solution with oxidants is typically used to convert H₂S into stable, non-volatile compounds. For BTEX and other organics, multi-stage designs and absorptive liquids can be applied. The final configuration is always based on the specific chemistry and operating envelope of the vessel.

Key benefits of gas scrubbers on well stimulation vessels

1. Protecting crew safety

Hydrogen sulphide and aromatic hydrocarbons can become life-threatening within seconds. A properly designed scrubber removes these components from the gas stream before they reach deck level, adding an essential layer of protection on top of gas detection and ventilation.

2. Meeting environmental requirements

Many offshore jurisdictions no longer accept uncontrolled venting of stimulation gases. Scrubbers significantly reduce VOC, BTEX and H₂S emissions, helping operators meet the environmental standards set by regulators and field operators.

3. Protecting equipment and topside assets

Acid vapours and sour gases are extremely aggressive towards steelwork, valves and deck equipment. By neutralising these components in the scrubbing liquor, the system extends the lifetime of topside hardware and reduces unplanned maintenance.

4. Handling highly dynamic flowback conditions

Flowback volumes and compositions can change rapidly as the stimulation sequence progresses. Ravebo scrubbers are engineered to cope with these dynamic conditions, including sudden peaks in gas flow or contaminant levels, so that safe operation can continue without interruption.

Why operators choose Ravebo for well stimulation scrubbers

Ravebo has decades of experience in custom wet gas scrubber systems for heavy industry and offshore applications. For well stimulation vessels we combine that process know-how with marine engineering practices:

- Compact footprint suitable for topside or below-deck installation.

- ATEX-compliant design and material selection for hazardous areas.

- Corrosion-resistant construction (e.g. special alloys, coatings, FRP where appropriate).

- Process-specific chemistry for H₂S, BTEX, CO₂ and acid vapours.

- High-efficiency droplet separation for dry, clean stack gas.

- Effluent handling concepts aligned with offshore disposal rules.

From concept and HAZOP support to detailed engineering, fabrication and commissioning, Ravebo delivers turnkey scrubber packages that fit seamlessly into the vessel’s stimulation spread.

Need a gas scrubber for your well stimulation vessel?

Ravebo designs and manufactures offshore-grade gas scrubbers for H₂S, BTEX, acid vapours and mixed hydrocarbon emissions in well stimulation service.

Contact our specialistsWell stimulation scrubbers – FAQ

What is a well stimulation vessel?

A well stimulation vessel is a specialised offshore ship used to enhance production from existing oil and gas wells. It pumps acids, solvents or stimulation fluids into the wellbore to remove formation damage, scale and blockages so that hydrocarbons can flow more easily.

Why does a well stimulation vessel need a gas scrubber?

Stimulation operations generate gas flows that can contain H₂S, BTEX, hydrocarbons and acid vapours. A gas scrubber removes or neutralises these contaminants before the gas is vented or further treated, protecting crew safety, equipment and environmental compliance.

Which gas components can be removed by the scrubber?

Depending on the chosen scrubbing concept, the system can remove hydrogen sulphide (H₂S), BTEX aromatics and other VOCs, acid vapours from HCl or other treatments, and fine aerosols or chemical mist present in the gas stream.

How is the scrubber integrated into the stimulation spread?

The scrubber is installed downstream of the flowback separator or knock-out drum. Separated gas enters the scrubber, passes through one or more scrubbing stages and a high-efficiency demister, and then leaves as treated gas that can be vented or directed to a flare or thermal oxidiser. The scrubbing liquor circuit and effluent handling are integrated with the vessel’s utilities.

Can a gas scrubber replace flaring?

In some projects, scrubbers reduce toxic and corrosive components enough to allow controlled venting where regulations permit. In others, the scrubber is placed upstream of a flare or thermal oxidiser to protect equipment and minimise overall emissions. Whether flaring is still required depends on the safety and environmental framework of the specific field.